型材弯曲机:概述分类特点与应用范围

型材是广泛使用的钢材料结构,规格多种多样。根据使用性能需要,常用的型材包括角钢、槽钢、工字钢、扁钢、圆钢等。一般先由专用模具挤压生产成型,然后再使用型材弯曲机等专业设备经过弯曲,冲压等工艺,再次加工成型。

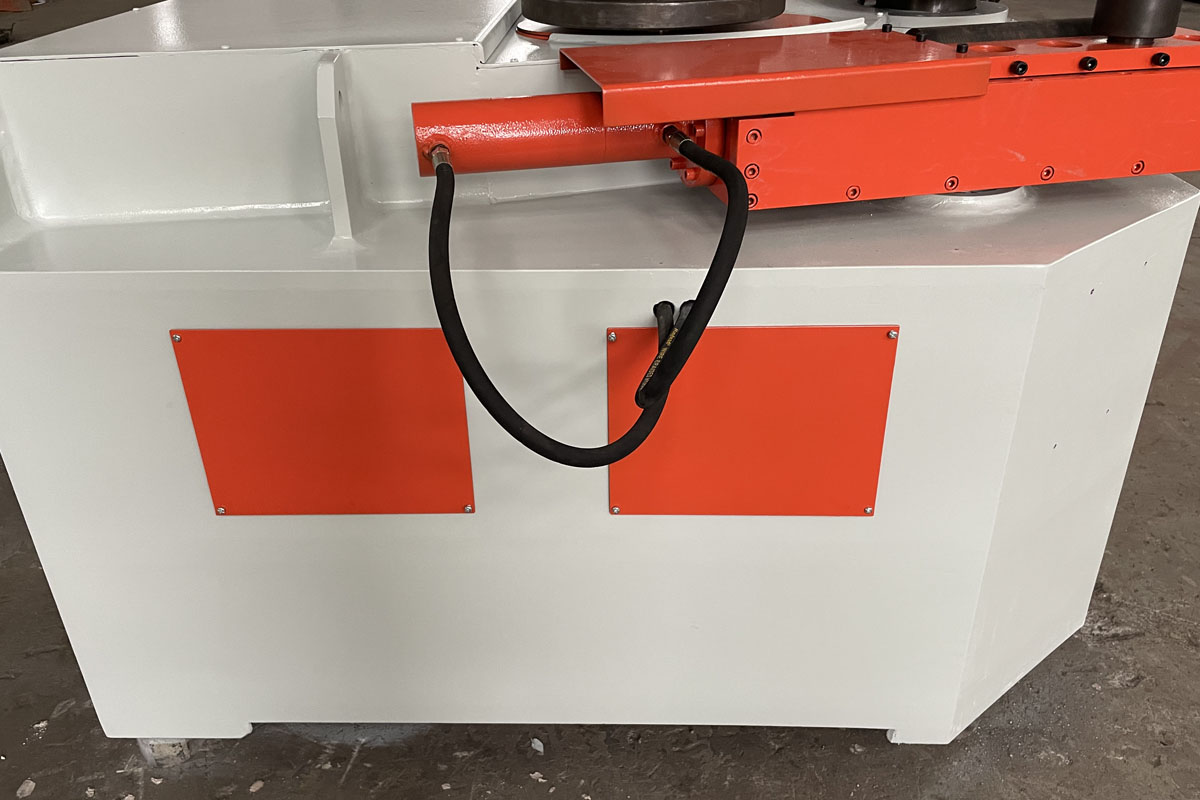

立式型材弯曲机是一种用于弯曲金属型材的设备,结构先进、功能全,可以一次性完成型材的预弯、卷圆和校圆等工序。型材弯曲机主要用于铝合金异型材、扁钢、方钢、圆钢、角钢、I型钢、H型钢、方管、矩形管、圆管等材料的加工。

Profiles are widely used steel structural materials, available in various specifications. Commonly used profiles include angle steel, channel steel, I-beams, flat steel, and round steel, depending on performance requirements. They are generally first extruded using specialized molds, and then further processed using specialized equipment such as profile bending machines through bending, stamping, and other processes.

A vertical profile bending machine is a device used for bending metal profiles. It features an advanced structure and comprehensive functions, capable of completing pre-bending, rolling, and rounding processes in a single operation.

Profile bending machines are mainly used for processing aluminum alloy profiles, flat steel, square steel, round steel, angle steel, I-beams, H-beams, square tubes, rectangular tubes, and round tubes.

立式型材弯曲机的分类

按轴布置分类

- 上调式 :上辊轴固定,下辊轴向上运动实现弯曲。

- 下调式 :上辊轴固定,下辊轴向下运动实现弯曲。

按工作辊数量分类

- 三辊主动式 :三个独立液压马达驱动,卷制速度快、精度高。

- 四辊主动式 :四个独立液压马达驱动,进一步提升了加工能力和精度。

Classification of Vertical Profile Bending Machines

Classification by Axis Arrangement

Top-Adjustable Type: The upper roller shaft is fixed, and the lower roller shaft moves upward to achieve bending.

Bottom-Adjustable Type: The upper roller shaft is fixed, and the lower roller shaft moves downward to achieve bending.

Classification by Number of Working Rollers

Three-Roll Active Type: Driven by three independent hydraulic motors, achieving high rolling speed and precision.

Four-Roll Active Type: Driven by four independent hydraulic motors, further enhancing processing capacity and precision.

型材弯曲机特点

- 采用弧线下调式结构,通过液压控制实现精确弯曲,卷制速度可达每小时数百米。

- 支持定制化模具,适应不同规格型材加工需求。

- 主动辊设计 :三辊或四辊主动驱动,减少传动误差,提升卷弯质量。

- 非对称截面处理 :配备托辊和矫正导向装置,确保角钢等非对称截面型材卷制精度。

- 一体化设计,可完成预弯、卷圆、校圆等多工序,降低生产复杂度。

Features of Profile Bending Machines

- Utilizes a curved downward-adjustable structure, achieving precise bending through hydraulic control, with rolling speeds reaching hundreds of meters per hour.

- Supports customized molds to adapt to the processing needs of different profile specifications.

- Active Roller Design: Three or four rollers actively driven, reducing transmission errors and improving bending quality.

- Asymmetric Section Processing: Equipped with support rollers and straightening guide devices to ensure the rolling accuracy of asymmetric section profiles such as angle steel.

- Integrated design, capable of completing multiple processes such as pre-bending, rolling, and straightening, reducing production complexity.

型材弯曲机的应用范围

- 汽车制造 :用于生产汽车框架和其他部件。

- 建筑行业 :用于钢结构的弯曲和成型7。

- 机械制造 :用于制造机械零件和结构件。

- 石油化工 :用于制造化工设备所需的管道和法兰。

- 电梯制造 :用于电梯导轨和其他部件的弯曲。

Applications of Profile Bending Machines

- Automotive Manufacturing: Used for producing automobile frames and other components.

- Construction Industry: Used for bending and forming steel structures.

- Machinery Manufacturing: Used for manufacturing machine parts and structural components.

- Petrochemical Industry: Used for manufacturing pipes and flanges required for chemical equipment.

- Elevator Manufacturing: Used for bending elevator guide rails and other components.

结论

立式型材弯曲机通过先进结构设计实现了高效、精准的型材弯曲,其性能稳定、操作简单、是现代制造业中理想的型材弯曲设备。

Conclusion

Vertical profile bending machines achieve efficient and precise profile bending through advanced structural design. Their stable performance and simple operation make them ideal profile bending equipment in modern manufacturing.

下一页: